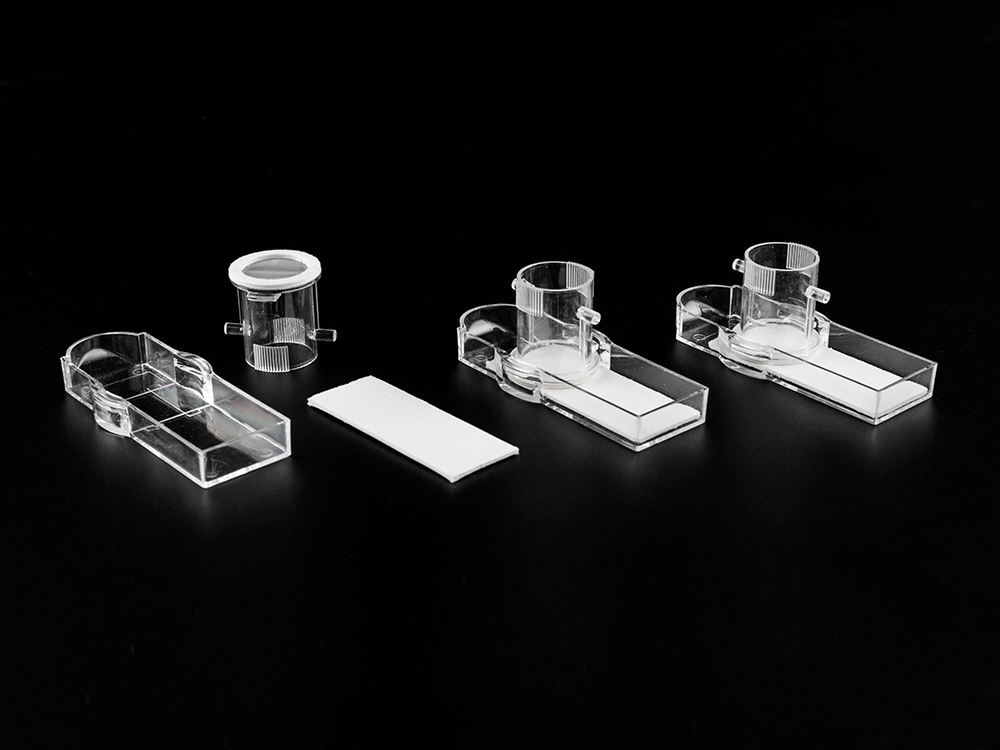

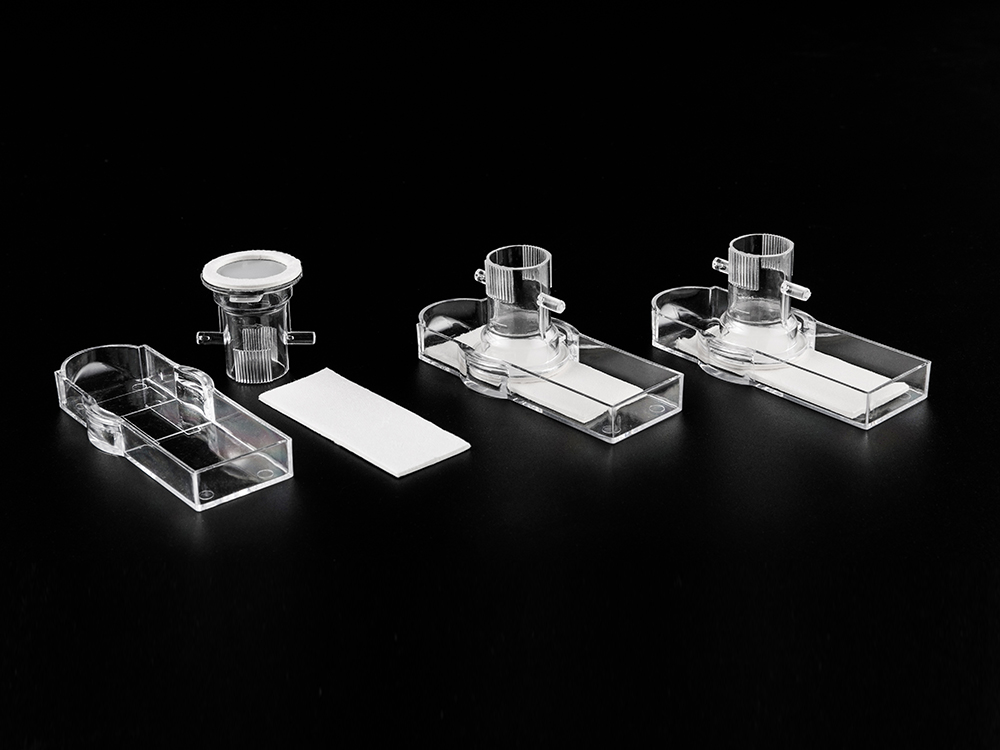

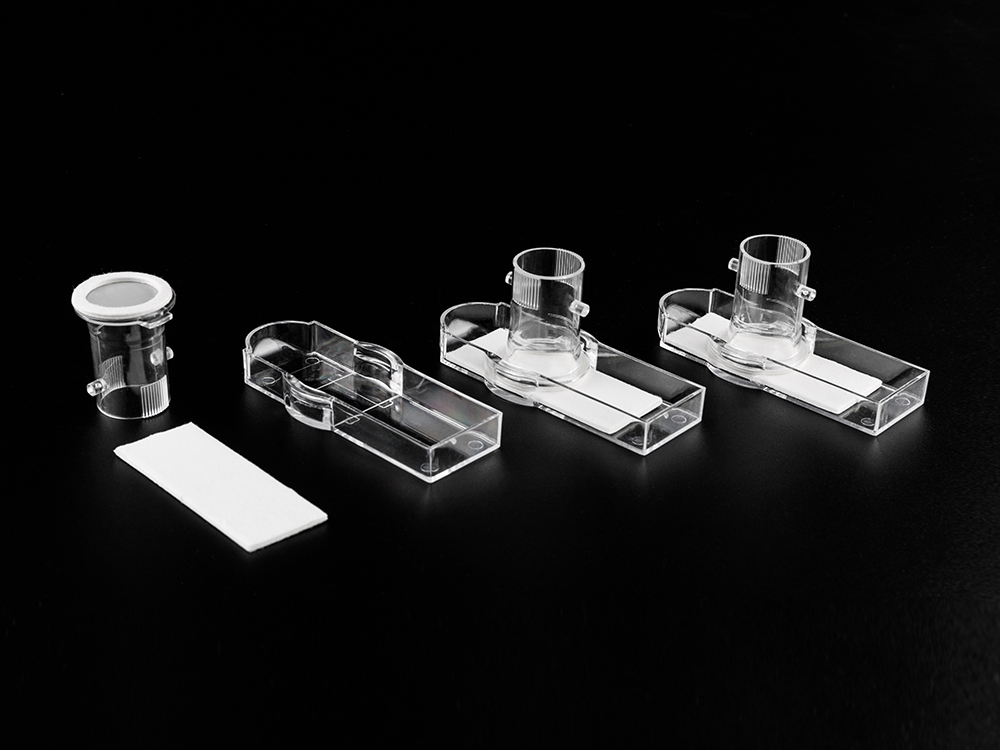

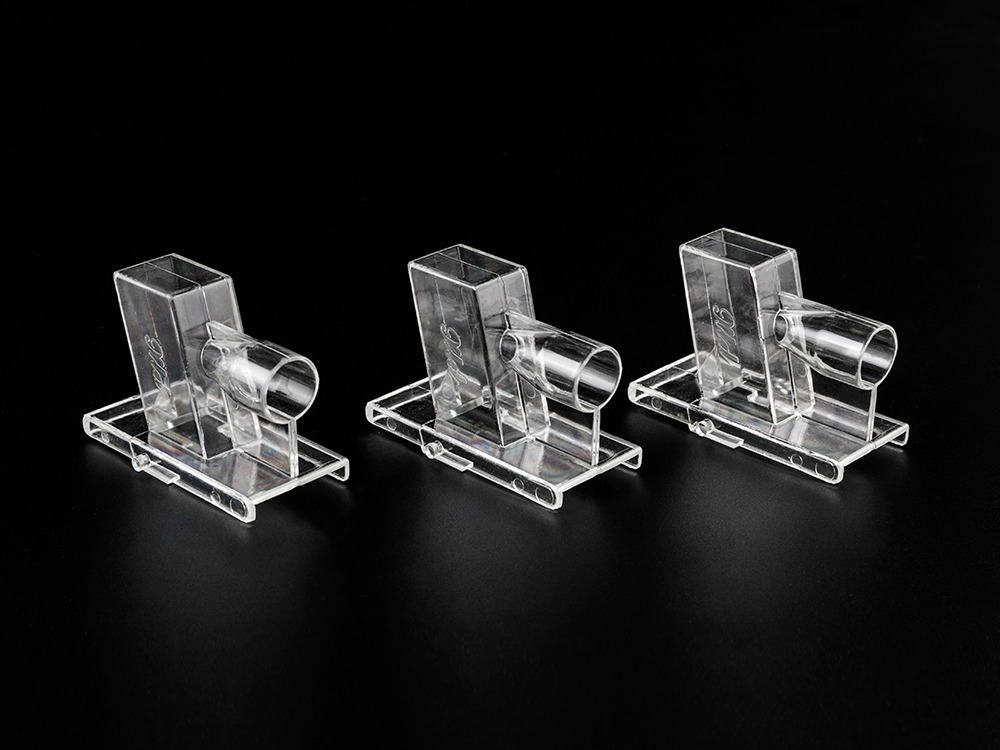

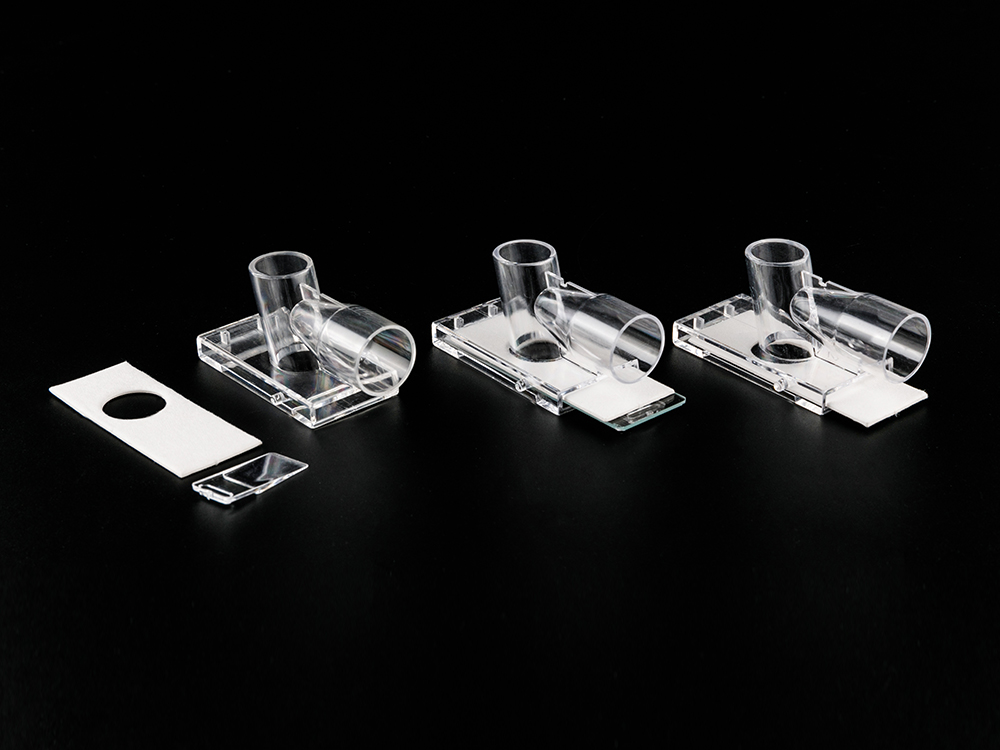

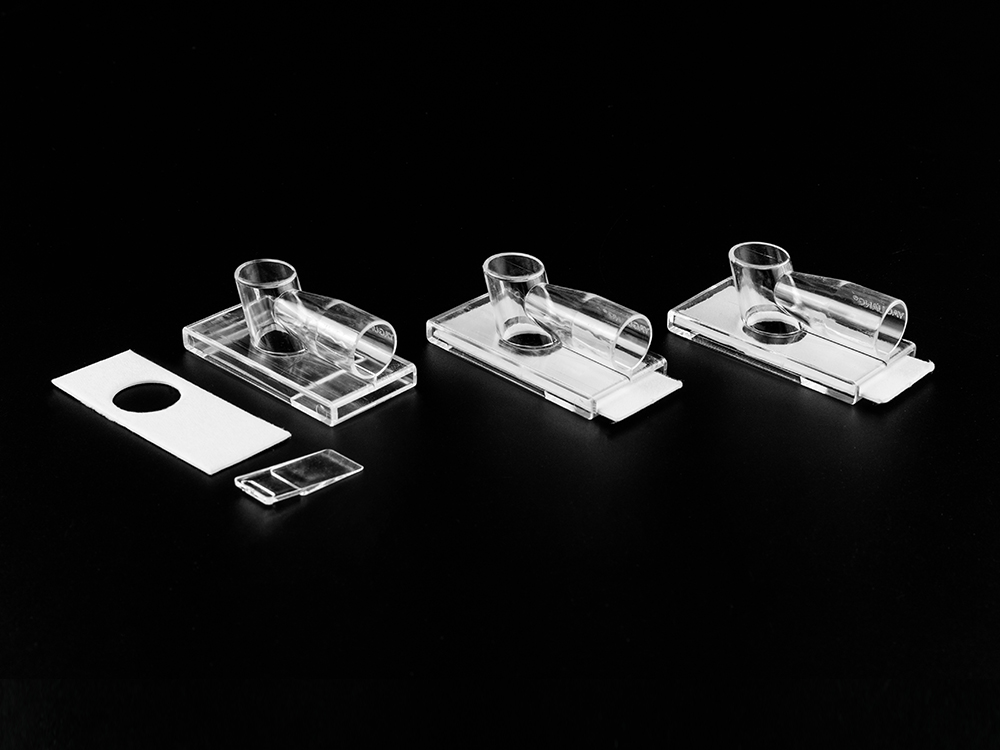

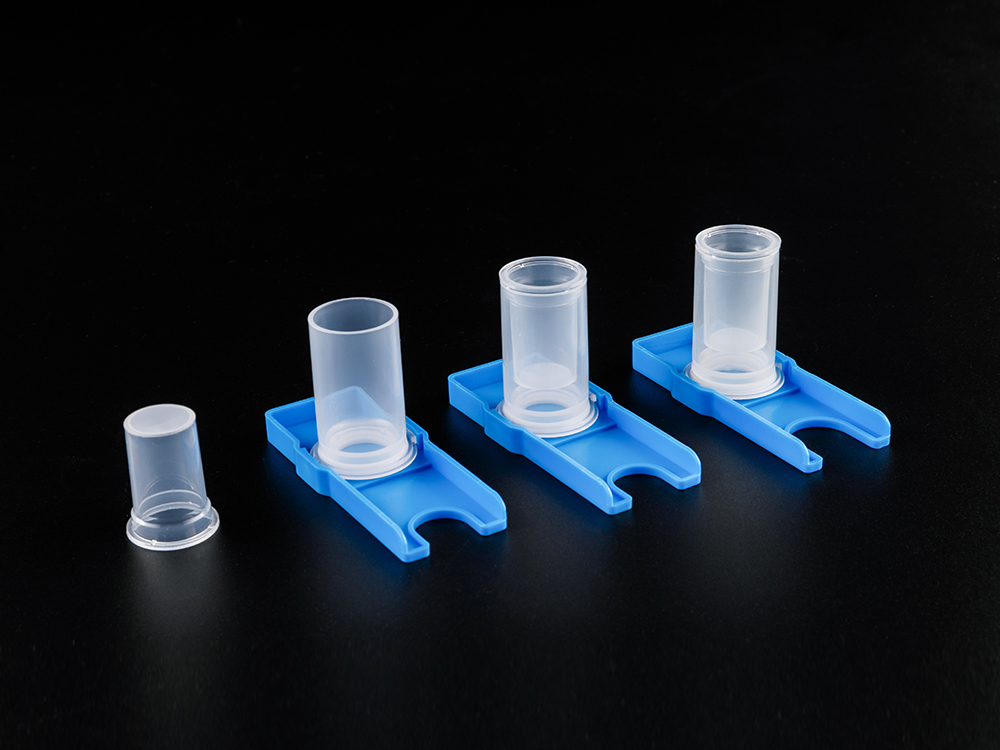

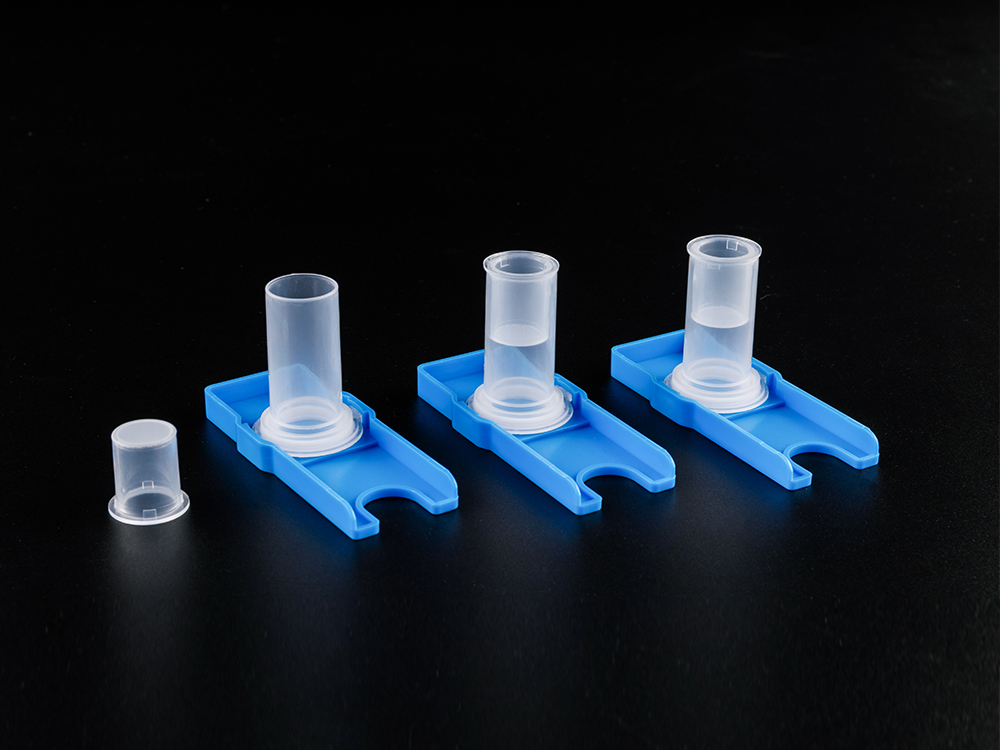

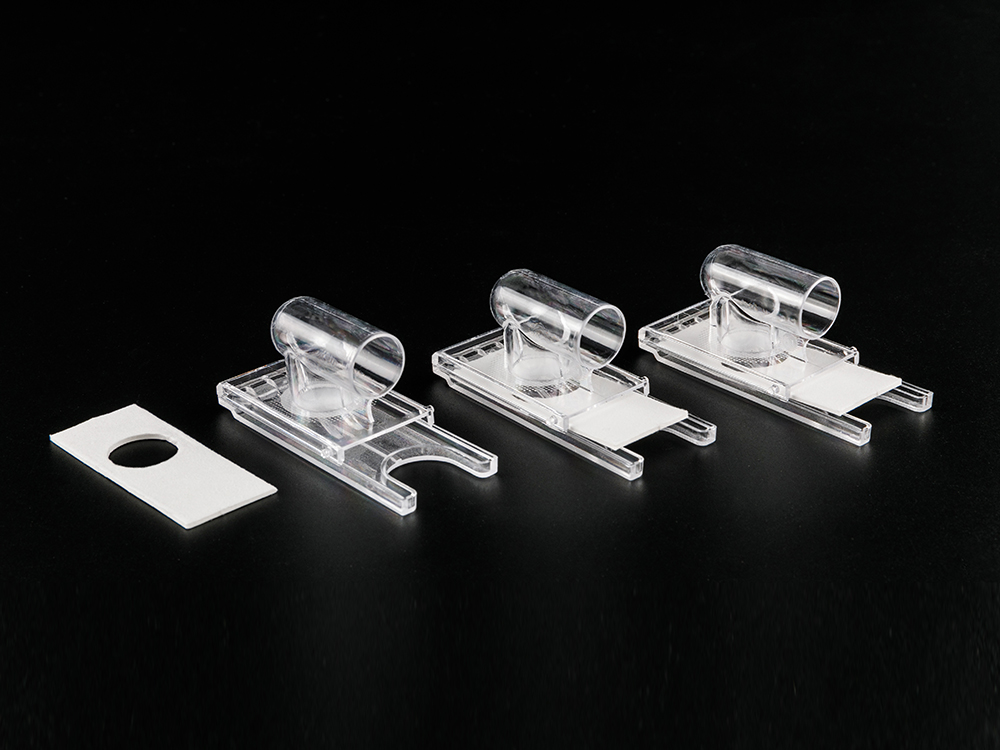

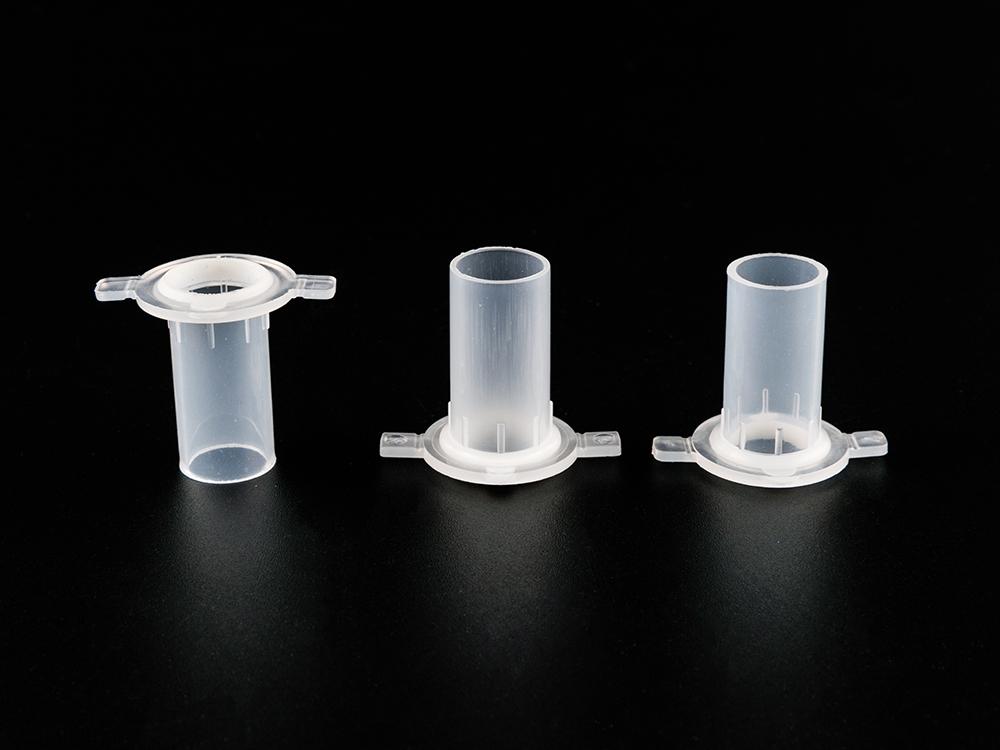

The Divided Embedding Cassette efficiently supports the multiple needs of modern pathology laboratories for sample safety, traceability and automated processing. In workflows such as high-throughput sectioning, special staining and molecular pathology, operators often need to open, close, transfer or re-label specimen containers multiple times; improperly structured embedding cassettes can easily cause tissue loss, blurred labels or deformation during chemical steps such as dehydration, transparency and wax dipping. To this end, we use a detachable two-piece base/cover structure, which is smooth to disassemble and assemble without the need for additional tools; even if the cover is frequently switched, the tissue sample can still be safely retained in the bottom grid, significantly reducing the risk of loss and improving operational confidence.

The main body of the box is made of POM engineering plastic. Its excellent dimensional stability and corrosion resistance to most commonly used tissue processing chemical reagents (such as formalin, alcohol gradient, xylene substitutes, etc.) enable the embedding box to maintain a complete structure and reliable fit in a long process and multiple bath cycles, providing a solid foundation for the subsequent embedding quality. The rationally designed buckle mechanism keeps the bottom cover firmly connected during the dehydrator, tissue processor and transportation process to prevent the parts from loosening due to impact or fluid scouring; at the same time, the buckle is evenly stressed and is not prone to fatigue damage after repeated opening, which prolongs the turnover life and helps control the cost of laboratory consumables.

Label management is also critical. The split tissue embedding box has a large handwriting area on both sides to meet the needs of rapid naked eye labeling, barcode rewriting or customized batch coding according to the department; the front end of the box is specially designed with a 45° inclined writing surface, so that the operator can write clearly by lowering the wrist angle under the conditions of gloves and protective masks, reducing ink smearing and improving reading efficiency. For laboratories pursuing standardized information flow, the cassette is compatible with most embedding cassette printers on the market, and can easily integrate barcodes, QR codes and pathology numbers to achieve full tracking from sampling, dehydration to sectioning.

With its stable structure, chemical-resistant materials, friendly writing interface and automation compatibility, the split tissue embedding cassette helps pathology departments, research institutions and biobanks maintain data accuracy, smooth processes and tissue integrity during the busy sample processing season. It is suitable for both daily routine pathology and multi-batch scientific research sample management, and is a reliable choice for laboratories to strike a balance between efficiency and quality.

In quality system audits (such as ISO 15189 and GLP scenarios), the requirements for sample container label clarity, chemical resistance and traceability record integrity are increasing; choosing an embedding cassette with a sophisticated structure, sufficient information carrier and matching with an automation platform is a detailed investment to reduce error rates, shorten turnaround time and increase audit pass rates. The split design also makes maintenance, classification cleaning and batch color code management more flexible, laying the foundation for continuous improvement of laboratory lean management.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch عربى

عربى