Today, as precision operation and liquid quantitative control are increasingly valued, plastic graduated droppers have gradually become an indispensable gadget in many fields such as medical care, laboratories and home care due to their simple structure, intuitive operation and safe use. Compared with traditional glass droppers, this type of plastic dropper not only has good corrosion resistance and fall resistance, but also because of its transparent material and clear scale design, the dosage control during liquid absorption and release is more accurate and intuitive, greatly improving the reliability and efficiency of the operation.

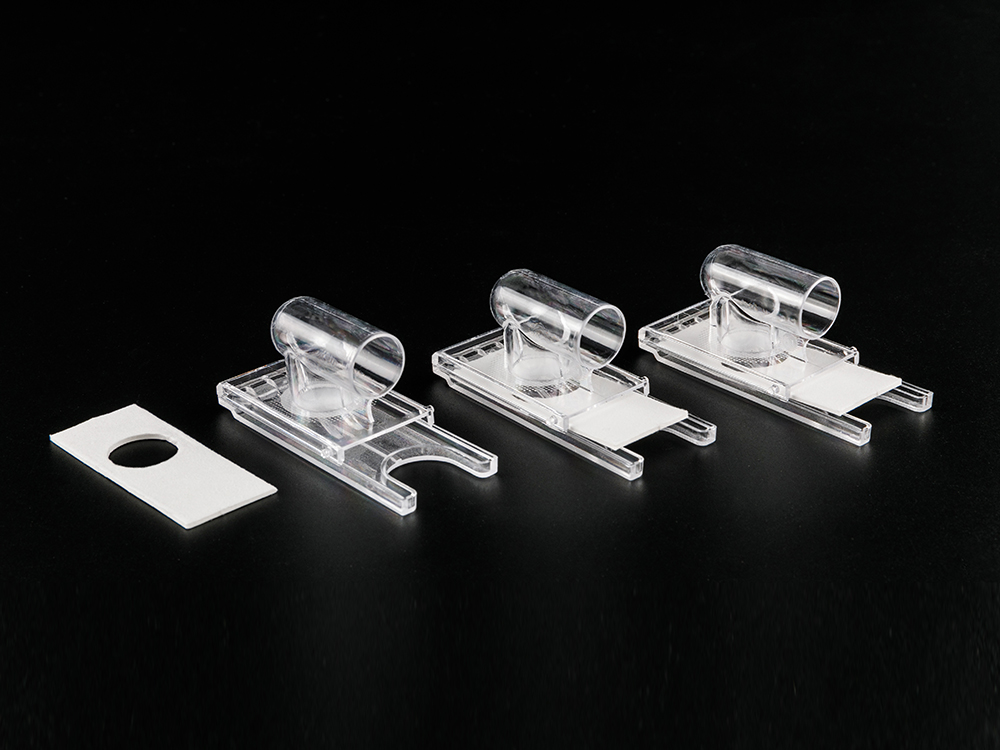

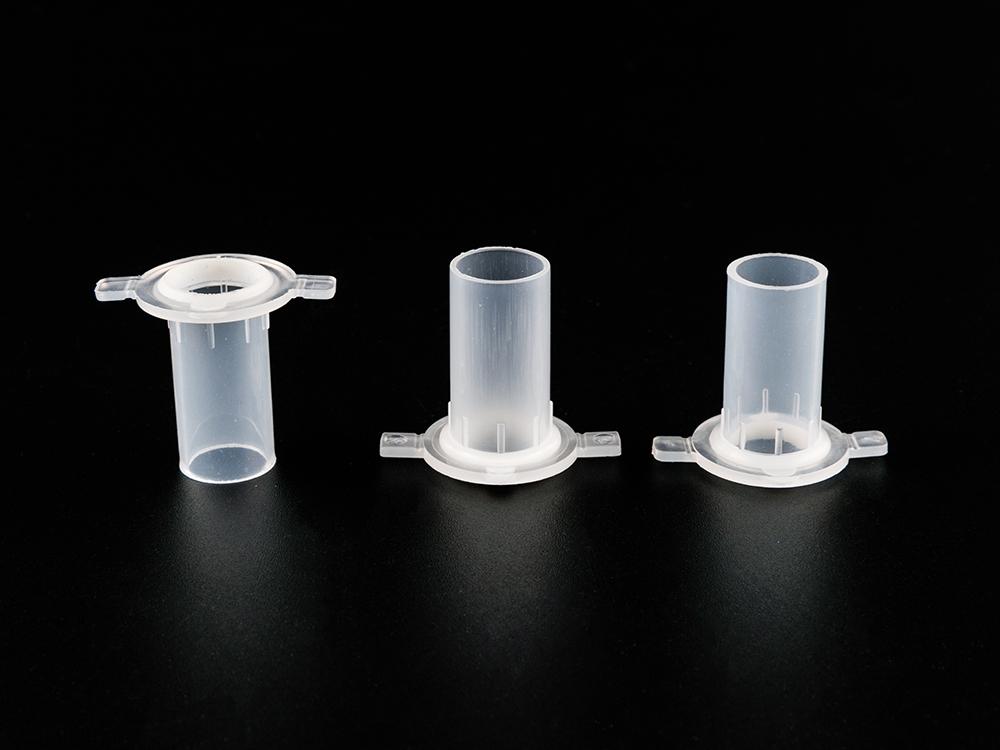

Plastic graduated droppers are generally made of polyethylene (PE) or polypropylene (PP) with good flexibility. The tube body is transparent and has printed or molded scales, which makes it easy for the operator to clearly observe the liquid volume. The liquid absorption ball part is mostly made of hot-pressed one-piece molding or firmly embedded technology, which not only ensures the airtightness of the dropper, but also ensures smoothness and safety during use. Because of its advantages of being light, economical, and easy to use, plastic graduated droppers are widely used in medical dispensing, chemical experiments, essential oil preparation, infant nutrition drip feeding, and other scenarios. They are particularly suitable for occasions that require small amounts of precise liquid addition.

In actual use, the operator only needs to lightly press the suction ball and slowly release it to absorb the required liquid. After judging the volume by the scale, lightly press to drip. The whole process does not require complex tools or superb skills to complete the task of micro-dispensing. However, despite its ease of use, the application of plastic graduated droppers still needs to follow some precautions. First, a dropper of a material that matches the corrosion resistance should be selected according to the nature of the liquid in contact to avoid errors caused by chemical reactions or material deformation. Secondly, to prevent cross-contamination, the dropper should be cleaned or replaced in time after use. Especially in laboratories or medical scenarios, it is not recommended to reuse the same dropper for different liquids. For applications that require high precision, you should pay more attention to whether the scale line is clear and whether it is blurred due to wear due to frequent use. In addition, although plastic materials are resistant to falling, they are easy to deform at high temperatures. Do not use them as transfer tools for high-temperature liquids or place them in high-temperature environments.

中文简体

中文简体 English

English Español

Español Deutsch

Deutsch عربى

عربى